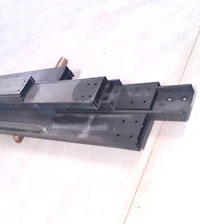

PR Kalars Purlins

Complete range of structural C and Z purlins

Pongalur roofings manunfacture a complete range of structural C and Z purlins and girts for industrial buildings, garages, verandahs and carports infact anywhere that strong reliable steel framing is required. Manufactured from quality cold rolled, hot rolled and galvanized steel, this is a fully integrated system allowing for flexible design options, supplied plain or punched, purlins are manufactured from high tensile steel for increased strength, reduced weight, and a long serviceable life.

PR Kalars produces an extensive purlin range with 8 web heights and 6 thickness combinations, from 75mm to massive 300mm purlins capable of impressive spans. Fascia purlins are also available in the larger sizes.

Galvanized CEE and ZED Purlins

High in strength, Low in cost

We offer purlins in galvanized coated steel in 120 GSM/175 GSM/275 GSM coating as per customer requirement. CEE and ZED galvanized purlins are secondary members of steel structures which serve as the basic material of construction for fast-track projects. These purlins are characterized by high strength, yet low cost. These purlins are supplied in required sizes and lengths with pre-punched holes for quick alignment. The production system deployed consists of international standard cold-roll forming and galvanizing technology using high quality machines for online measuring, cutting, punchin and forming to provide assured dimensions and strengthness and overall supreme quality product.

Purlins are widely used in commercial, industrial and rural buildings, steel structure, sheds and awnings as well as in racking and wall framings.

HR and CR, C and Z purlins

Special treatment to combat severe atmospheric corrosion can be offered.

CEE and ZED purlins made of hot rolled coils are de-greased, phosphated, and then primer finished with Zinc Chromate, Red Oxide paint matching test requirement of IS:4777 and IS:2074. Special treatment to combat severe atmospheric corrosion can be offered.

Service and Support:

Service:

PR Kalars offers the fastest service in town. Installation of new state of the art machinery allows not only faster production times, but greater flexibility to meet your needs. Contact your local stratco office for lead times when planning your next purlin project.

Bridging:

"Rapid fix" bridging is a very fast and easy to install system developed with your installer in mind. The receiver end has a unique locator tag that allows both ends to be held in place. Installation is easier and faster for the rigger who is operating well off the ground, Often in windy and difficult conditions. Rapidfix will save both time and money.

Competitive Prices:

Experienced technical representatives are able to advise you on pricing and delivery requirements. Our pricing is competitive and we ask only for the opportunity to provide a price for your next project

Engineering Support:

PR Kalars engineers have carried out extensive testing on both purlins and girts and on the "rapidfix" bridging system. Capacity tables have been calculated in accordance with limit state design principles and complies with Australian/New Zealand standard AS/NZ 4600:1996 cold formed steel structures,using the latest software developed by the centre for advanced structural engineering at the university of sydney. They are your guarantee of strength and structural sufficiency.

Quality:

Stracto purlins are crisp, clean and square and by any assessment are a quality product. There is no need to tolerate rounded corners, inaccurate lengths, or out of square purlins any more. Insist on quality stracto purlins for your project.

Advantages of CEE and ZED Purlins

1. Very high strength to weight ratio: high strength - low cost.

2. More than 40% savings in steel.

3. More than 30% savings in overall construction cost.

4. Easy and low cost handling and transportation.

5. Economy due to reduction in dead weight on the main frame structure.

6. Significantly reduces installation time.

7. Ability to span long lengths.

8. No site drilling or cutting required.

9. Maintenance free owing to application of proper surface finish.

10. Purlins are factory finished, cut to exact lengths with pre-punched holes to avoid wastage of time and material.

11. Continuous splay and splicing for better structural strength, stability and economy.

12. 45 degree lip for better sectional modules and easy nesting.

Technical Specifications:

Thickness : 1.5mm to 3.0mm

Length : upto 1200mm

Material : CR Steel as per IS:513/HR Steel as per IS:1079

Yield : 245 MPa to 345 MPa Strength

Type : Bare, Primer coated, galvanized, painted